by Greenly Water Saver | Nov 10, 2025 | GoGreen

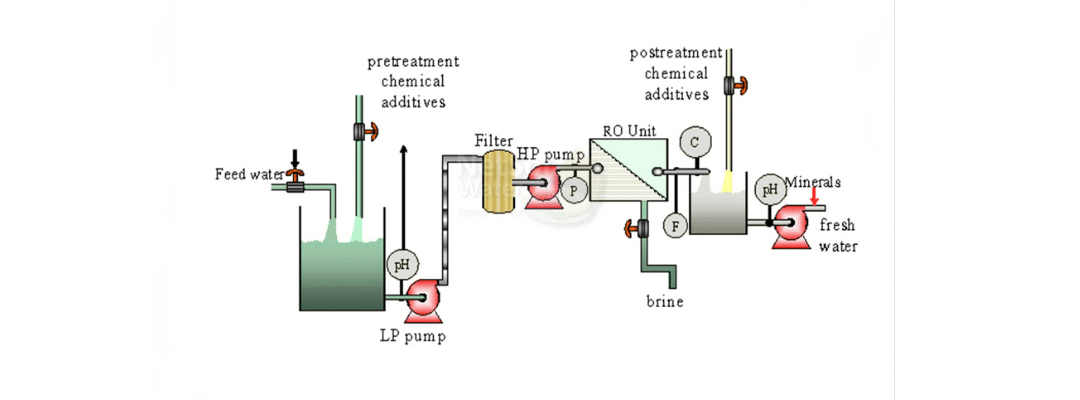

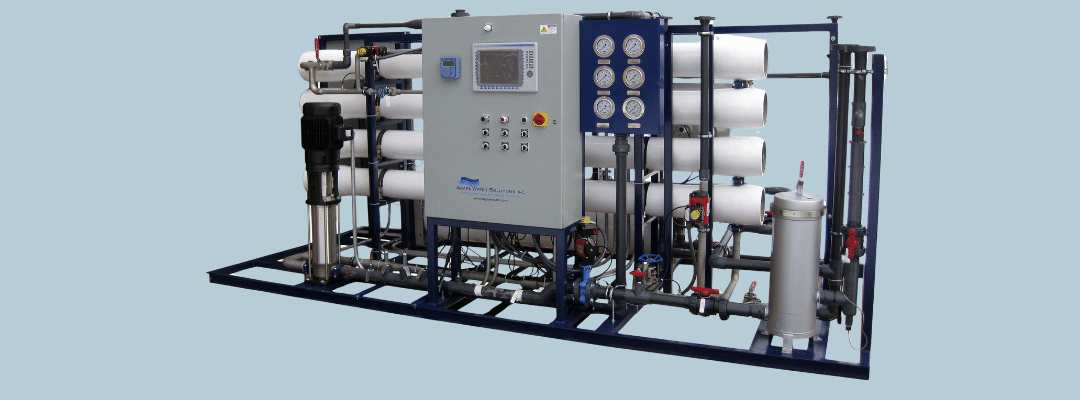

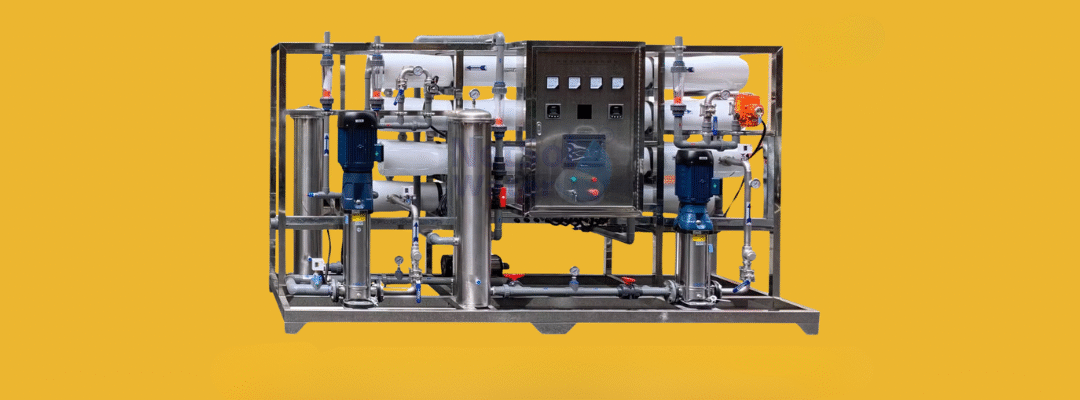

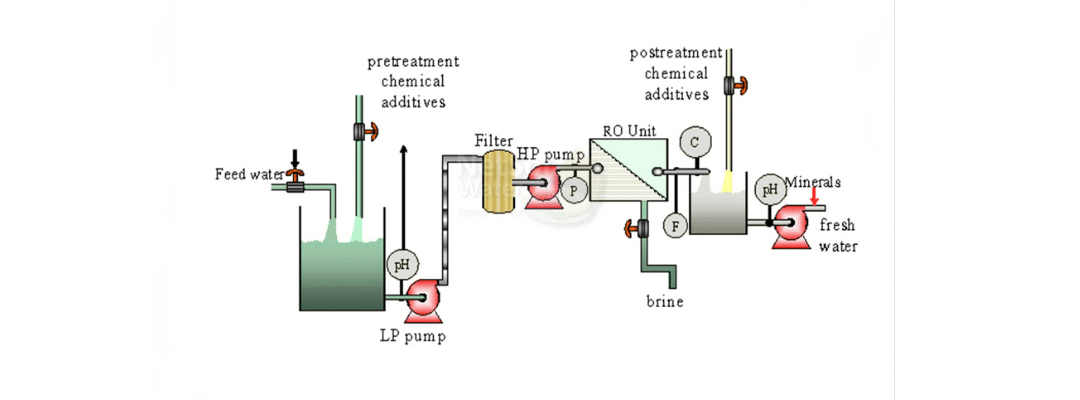

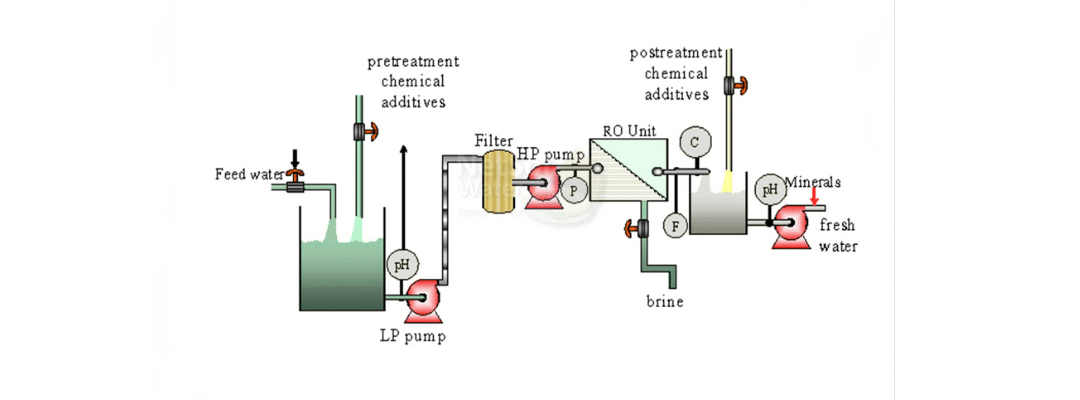

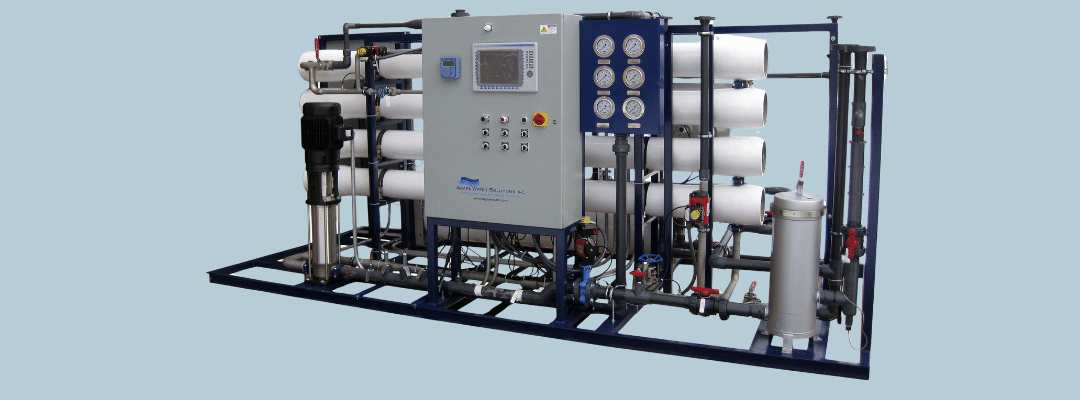

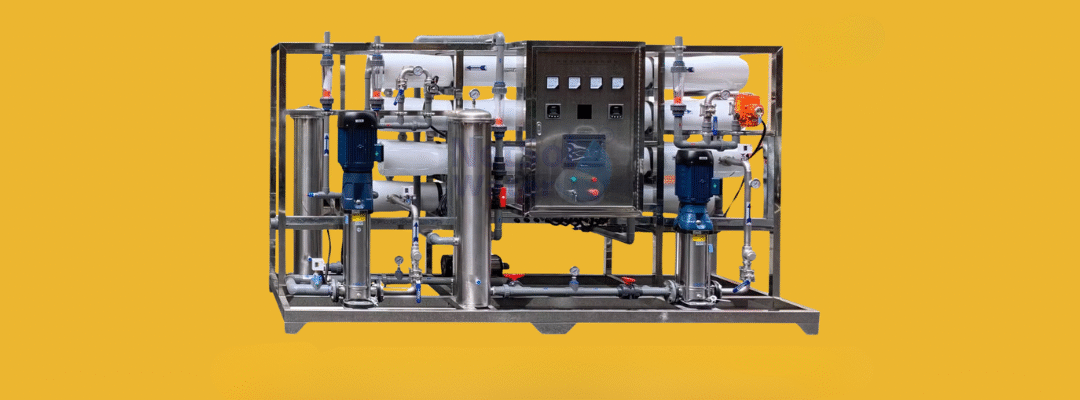

Designing an Industrial Reverse Osmosis (RO) Water Plant requires a blend of engineering precision, water chemistry insight, and system automation. Whether you’re building an RO system for manufacturing, food processing, pharma, or utilities, the plant must...

by Greenly Water Saver | Nov 10, 2025 | GoGreen

In modern water treatment, automation isn’t just an upgrade—it’s essential.As industries demand precise, consistent, and hands-free operation, automated RO (Reverse Osmosis) systems using PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data...

by Greenly Water Saver | Nov 9, 2025 | GoGreen

Even a well-designed Reverse Osmosis (RO) plant is not immune to performance issues. Factors like feed water variability, aging components, and inconsistent maintenance can lead to: Low water output Rising TDS levels Pressure imbalances Membrane scaling or fouling...

by Greenly Water Saver | Nov 9, 2025 | GoGreen

Reverse Osmosis (RO) systems are critical in providing high-purity water across industries, institutions, and commercial facilities. However, not all RO setups offer the same level of water purification. The system configuration—whether it’s Single Pass or...

by Greenly Water Saver | Nov 8, 2025 | GoGreen

Industrial and municipal sectors generate massive amounts of wastewater, often laden with salts, chemicals, and heavy metals. Discharging this untreated water not only harms ecosystems but squanders a valuable resource. With modern technologies like Reverse Osmosis...

by Greenly Water Saver | Nov 8, 2025 | GoGreen

In every Reverse Osmosis (RO) water treatment system, the membrane is the heart of the operation — responsible for removing dissolved salts, metals, and impurities. However, RO membranes gradually lose efficiency due to fouling, a common issue involving the...

Recent Comments