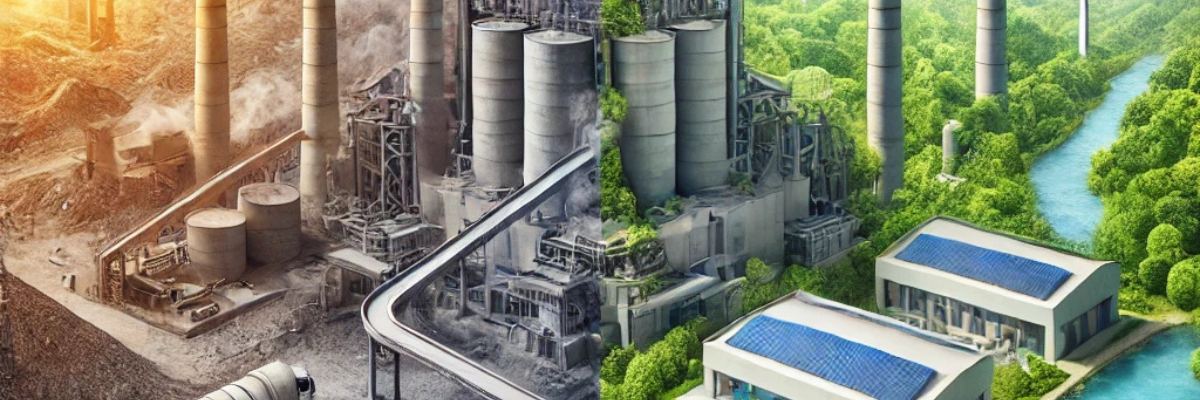

Pollution in Cement plants

Cement plants are significant sources of various types of pollution, impacting air, water, and land. Here’s a breakdown of the primary types of pollution in cement plants:

Cement production releases significant amounts of air pollutants, primarily due to combustion processes and material handling. Key pollutants include:

- Particulate Matter (PM): Dust from raw materials, clinker, and cement grinding.

- Nitrogen Oxides (NOx): Produced during the high-temperature combustion process.

- Sulfur Oxides (SOx): Emitted from the sulfur content in raw materials and fuels.

- Carbon Dioxide (CO2): A significant greenhouse gas, mainly from the calcination of limestone and fuel combustion.

- Volatile Organic Compounds (VOCs): Released during raw material heating and fuel burning.

- Heavy Metals: Trace elements like mercury, lead, and cadmium from raw materials and fuels.

2. Water Pollution

Although water pollution is less prevalent, cement plants can still impact local water systems:

- Effluent Discharge: Contaminated water from cooling, washing, or chemical processes.

- Alkaline Runoff: High pH water resulting from the interaction of water with cement dust or clinker.

- Groundwater Contamination: Seepage of chemicals or fine particulates into the water table.

3. Land Pollution

Land degradation around cement plants occurs due to:

- Solid Waste: Accumulation of unused raw materials, waste products, and packaging materials.

- Quarrying Impact: Mining of limestone and other raw materials alters the landscape and leads to soil erosion.

- Clinker and Ash Residue: Improper disposal can contaminate soil.

4. Noise Pollution

Cement plants generate high levels of noise pollution from:

- Crushers

- Grinding mills

- Rotary kilns

- Blowers and fans

This can disrupt local communities and wildlife

5. Thermal Pollution

The heat generated during cement production can cause localized increases in temperature, affecting ecosystems around the plant.

Mitigation Measures

- Air Pollution: Use of electrostatic precipitators, bag filters, and wet scrubbers.

- Water Pollution: Proper effluent treatment systems and rainwater harvesting.

- Land Pollution: Sustainable quarrying practices and recycling of waste materials.

- Noise Pollution: Installation of soundproofing systems and proper maintenance of equipment.

Reducing pollution in cement plants is crucial to minimize environmental impact and promote sustainability.

Reducing pollution in cement plants is essential for minimizing environmental impact and enhancing sustainability. Here are effective strategies to reduce various types of pollution in cement plants:

1. Reducing Air Pollution

- Install Air Pollution Control Devices:

- Electrostatic Precipitators (ESP): Captures fine dust particles from emissions.

- Baghouse Filters: Filters particulates from kiln and grinding processes.

- Wet Scrubbers: Reduces sulfur oxides (SOx) and dust by spraying water.

- Use Alternative Fuels and Raw Materials (AFR):

- Replace fossil fuels with waste-derived fuels like biomass or industrial waste.

- Use raw materials with lower sulfur and heavy metal content.

- Improve Process Efficiency:

- Optimize combustion efficiency to reduce NOx emissions.

- Install low-NOx burners and use selective catalytic reduction (SCR) technologies.

- Adopt Carbon Capture and Storage (CCS):

- Capture CO2 emissions for storage or reuse.

- Reduce Dust Generation:

- Use enclosed conveyors and transfer points.

- Regularly maintain and clean equipment to prevent dust leaks.

2. Mitigating Water Pollution

- Effluent Treatment:

- Treat wastewater from cooling and cleaning processes to remove contaminants before discharge.

- Reuse Water:

- Implement water recycling systems for cooling and cleaning processes.

- Prevent Runoff:

- Use bunds or containment areas to prevent alkaline water runoff from contaminating nearby water bodies.

3. Minimizing Land Pollution

- Proper Waste Management:

- Recycle solid waste like clinker and gypsum residue.

- Utilize waste materials like fly ash and slag in cement production.

- Sustainable Quarrying:

- Adopt responsible mining practices to reduce land degradation.

- Reclaim and restore mined areas through afforestation or landscaping.

4. Reducing Noise Pollution

- Install Noise Barriers:

- Use soundproof enclosures for noisy equipment like crushers and kilns.

- Optimize Equipment Operation:

- Regular maintenance to minimize noise from worn-out machinery.

- Restrict Operating Hours:

- Limit noisy operations during community-sensitive times.

5. Addressing Thermal Pollution

- Waste Heat Recovery (WHR):

- Install waste heat recovery systems to capture and reuse heat for power generation.

- Efficient Insulation:

- Properly insulate equipment to prevent heat loss and reduce environmental temperature rise

6. Reducing Carbon Footprint

- Switch to Alternative Energy Sources:

- Use renewable energy like solar or wind to power operations.

- Blended Cement Production:

- Reduce the clinker-to-cement ratio by using supplementary materials like fly ash, slag, or pozzolana.

- Adopt Green Cement Technologies:

- Use low-carbon cement production methods, such as geopolymer cement.

7. Monitoring and Compliance

- Continuous Emission Monitoring Systems (CEMS):

- Install systems to monitor emissions in real-time and ensure regulatory compliance.

- Environmental Audits:

- Conduct regular audits to identify and rectify pollution sources.

8. Employee and Community Engagement

- Training Programs:

- Educate employees about pollution reduction techniques and practices.

- Community Engagement:

- Collaborate with local communities to address concerns and implement eco-friendly initiatives.

By implementing these measures, cement plants can significantly reduce their environmental impact while enhancing operational efficiency and sustainability.

Recent Comments