Designing an Industrial Reverse Osmosis (RO) Water Plant requires a blend of engineering precision, water chemistry insight, and system automation.

Whether you’re building an RO system for manufacturing, food processing, pharma, or utilities, the plant must match raw water quality, daily demand, target recovery, and end-use standards.

This guide explains how to design an RO plant step-by-step — from lab water testing to component selection, membrane array design, and PLC-SCADA integration.

1. Analyze Raw Water Quality

Water quality defines the entire plant design, especially pretreatment and membrane selection.

Key Parameters:

| Parameter | Ideal Range | Impact |

|---|---|---|

| TDS | 200 – 2000 ppm | Affects membrane & recovery |

| Hardness | < 200 ppm | Causes membrane scaling |

| Iron / Manganese | < 0.3 ppm | Membrane fouling risk |

| pH | 6.5 – 8.0 | Outside range damages membranes |

| Turbidity | < 1 NTU | Clogs filters |

| Chlorine | 0 ppm | Destroys polyamide membranes |

| SDI | < 5 | Predicts membrane safety |

Tip: Use NABL-certified lab reports or inline meters for quick estimates.

2. Define Daily Water Requirement

Understand your industry’s RO water use cases:

| Industry | RO Water Used For |

| F&B | Ingredient & cleaning water |

| Pharma | PW & sterile washing |

| Power | Boiler feed, cooling |

| Electronics | Rinsing, prep |

Formula:

Daily Demand (L/day) = LPH Needed × No. of Operating Hours

3. Choose System Capacity & Recovery

| Feed Source | Recovery | Pressure | Membrane |

| Municipal (<500 ppm) | 70-80% | 10-15 bar | LPRO |

| Borewell (500–2000 ppm) | 60–70% | 15-25 bar | BWRO |

| Seawater (>10,000 ppm) | 35-45% | 50-70 bar | SWRO |

Example: 5000 LPH at 70% recovery → Feed = 7140 LPH

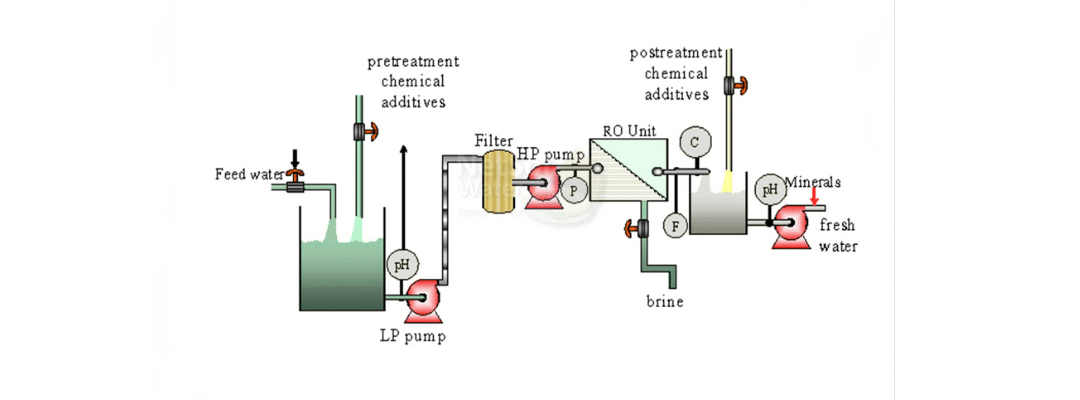

4. Design the Pretreatment System

Standard pretreatment train:

- Raw Water Pump

- MMF (sand + gravel)

- ACF (removes chlorine/odor)

- Water Softener or Antiscalant Dosing

- Micron Filter (5–20 µm)

- pH Correction (if needed)

Sizing depends on flow rate, media depth, and pressure drop.

5. Configure the Membrane System

a) Membrane Type

- BWRO 8040 TFC Membranes for 500–2000 ppm feed

b) Membrane Array

| Flow (LPH) | Array Design |

| 1000–2000 | 1:1 |

| 5000 | 2:1 |

| 10,000+ | 2:2 or 3:2 |

6. Add Post-Treatment (If Needed)

- UV/Ozone: For microbial disinfection

- Mineral Cartridge: Taste correction / pH balancing

- DI/Mixed Bed: For ultrapure applications

- SS Tanks: For hygiene storage

7. Integrate Control & Automation

Use PLC + SCADA for intelligent RO control:

- Auto start/stop

- Flow, pressure, TDS sensors

- Membrane flushing logic

- Chemical dosing logic

- Alarm & safety interlocks

- Remote SCADA dashboard (IoT optional)

SCADA improves visibility, audit tracking, and preventive maintenance.

8. Choose Material of Construction (MOC)

| Component | Recommended MOC |

| Pressure Vessels | FRP or SS 304/316 |

| Piping | UPVC / CPVC / SS |

| Filters | FRP / MSRL |

| Skid | MS Powder Coated or SS |

| Tanks | HDPE / SS / FRP |

9. Optimize Efficiency

- Install VFDs for pump energy savings

- Use high-recovery membranes

- Recycle reject water (gardening, flushing)

- Monitor with flow/pressure transmitters

10. Final Testing & Documentation

Before commissioning:

- Hydraulic test (leak check)

- 24-hour trial run

- Prepare documents:

- P&ID

- Membrane design sheet

- Panel wiring diagram

- SOPs

Design Example: 5000 LPH Plan

| Parameter | Value |

| Feed TDS | 1500 ppm |

| Recovery | 70% |

| Membrane | 2 BWRO 8040s in 2:1 array |

| Pressure | 16 bar |

| Pretreatment | MMF + ACF + Antiscalant + Micron |

| Post-Treatment | UV + Mineral Cartridge |

| Control | PLC + HMI |

| Power | 8 HP Total |

FAQs

Q1. How is LPH capacity calculated?

Divide daily need by operating hours. Adjust for recovery.

Q2. Best membrane for 1000–2000 ppm water?

Brackish Water RO (BWRO) membranes.

Q3. Can I reuse RO reject?

Yes, for non-potable uses like flushing or gardening.

Q4. How long do membranes last?

3–5 years with good maintenance.

Q5. How can I reduce energy use?

Use VFDs, optimize recovery, and automate flushing.

Recent Comments