Everything to know about the basic types of hydrogen as energy sources

There is a growing interest in the hydrogen energy debate. A product that was once a specialized feedstock for heavy industry is now at the forefront of decarbonizing transportation and shipping. Projects aimed at assisting in the achievement of net-zero goals and the production of zero-emission fuel are receiving investments totaling hundreds of billions of dollars. Grey Hydrogen is the most common kind of hydrogen. It is made by burning fossil fuels, and the process makes carbon dioxide, which can’t be used to make hydrogen.

Steam methane reforming (SMR) is the method that is used to make hydrogen from natural gas. In this method, high-temperature steam (700°C–1,000°C) is used to make hydrogen from a methane source like natural gas. In steam methane reforming, methane reacts with steam at pressures ranging from 3 to 25 bar (1 bar equals 14.5 pounds per square inch) in the presence of a catalyst to produce hydrogen, carbon monoxide, and a small amount of carbon dioxide. Endothermic steam reforming necessitates the addition of heat to the process in order for the reaction to take place.

There is likewise a gasification cycle which utilizations coal as a feedstock, making earthy colored hydrogen, which likewise delivers carbon dioxide and can be placed in a similar class as dim.

Enel, a global leader in renewable energy, has a head of business development who has referred to hydrogen as a “climate killer” because nearly all of it is gray: 98% of it is created from steam improving and gasification, which likens to yearly fossil fuel byproducts equivalent to that of Indonesia and the UK joined,” he said. ” Electrolysis produces only 2 percent.

Therefore, grey hydrogen is clearly not an option for the long term.

Blue Hydrogen follows the same carbon capture and storage cycle as grey, but the carbon is captured and stored this time. This makes it much better for the environment, but it also adds new technical difficulties and costs a lot more. Heavy industry and power generation companies use carbon capture and storage (CCS) technology, which has been around for a while. Although it isn’t perfect, the technology can capture up to 90% of the CO2 that is produced.

The majority of the time, this CO2 is transported via pipeline to salt caverns or depleted oil and gas reservoirs where it is stored deep underground. It may be more cost-effective to develop green hydrogen as their primary solution in nations that do not have access to such underground options. Establishing a blue hydrogen industry will be extremely challenging for these nations.

The goal of some forward-thinking organizations is to become carbon negative by using biomass fuels and carbon capture and storage (CCS). Blue hydrogen has been shown to be contentious among professionals in the industry and is frequently viewed as a stepping stone from grey to green when it comes to the production of hydrogen.

On the one hand, scaling up from the current production of grey hydrogen is relatively simple and uses less electricity. It is also independent of the explosive and unstoppable expansion of renewable energy sources like offshore wind and solar.

Green hydrogen advocates and think tanks, on the other hand, argue that blue hydrogen goes against net-zero’s goals and principles and is also more expensive than green in the medium term. Green Hydrogen- A net-zero world in which all of our fuel and electricity are produced from emission-free sources is the utopian vision of the future. It has the potential to play a significant role in resolving the majority of renewable energy sources’ intermittent generation capacity. Hydrogen can be produced from excess electricity and stored as a gas or liquid until needed.

It faces a lot of obstacles, but the momentum behind it is growing because governments all over the world are realizing the potential benefits and working on policies to encourage development and adoption.

What precisely is green hydrogen?

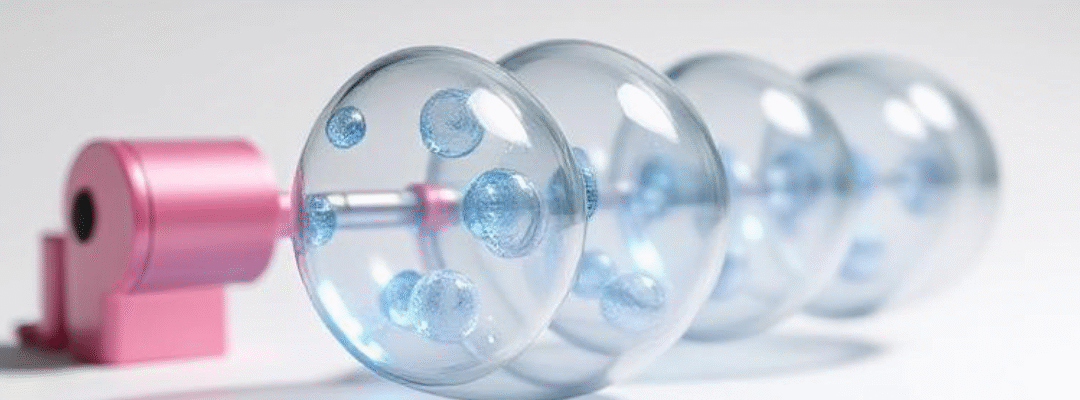

Green hydrogen is produced by separating water into hydrogen and oxygen through an electrolysis process instead of fossil fuels. The hydrogen is referred to as being green if that process is powered by a renewable energy source like wind or solar power.

What obstacles are there?

Green hydrogen technology necessitates the construction of larger-than-expected electrolysers.

1 Transportation and Storage Either extremely high temperatures or extremely high pressures are required, both of which present their own set of technical challenges.

2 Cost: According to Bloomberg New Energy Finance, the price of green hydrogen per kilogram can be reduced to a benchmark of $2/kg by 2050 in order to become competitive. Green hydrogen can compete with natural gas at these prices.

3 According to Simon Blakey, a senior adviser for global gas at IHS Markit, “Costs for producing green hydrogen have fallen by 50% since 2015 and could be reduced by an additional 30% by 2026 due to the benefits of increased scale and more standardized manufacturing, among other factors.”

4 Electricity To meet global targets, a staggering increase in wind and solar power is required because green hydrogen production requires a significant amount of electricity.

5 According to some current estimates, we will need to add more offshore wind capacity each year for the next 30 years than we did in the previous 20 years.

These are significant difficulties, however a great deal of them is as of now being overwhelmed by unbelievable designers and researchers. We can be sure that green hydrogen will prove to be the amazing energy solution we require with the right backing.

Over 30 nations have announced over 200 projects and invested over $300 billion in them. The fundamental players right now are Australia and Europe, with each taking on a somewhat unique methodology. Australia has made hydrogen a top priority, aiming to produce clean and green hydrogen for less than $2 per kilogram.

The European Union has developed “hydrogen valleys” that use the North Sea’s offshore wind capacity to power electrolysers and has established a clean hydrogen alliance. Utilizing the existing natural gas pipeline network to facilitate hydrogen transportation across the continent is the longer-term strategy.

Saudi Arabia recently announced its intention to enter the market, bringing their vast solar power potential and expertise in the construction of significant energy projects to bear.

Japan has developed a project that may have numerous applications: utilizing a carbon-neutral method to convert sewage into hydrogen. Every nation with sewage treatment facilities could adopt this, allowing hydrogen production locally and reducing the need for transportation.

Recent Comments