In the hospitality and healthcare sectors, water quality is non-negotiable. It directly affects safety, hygiene, comfort, and trust — whether it’s for drinking, cooking, cleaning, or medical procedures.

Hotels need clean, odor-free water for guest rooms, laundries, kitchens, and pools, while hospitals demand microbiologically safe and mineral-balanced water for patient care, equipment sterilization, and laboratories.

This is where RO (Reverse Osmosis) Water Plants offer the perfect solution — delivering consistent, high-purity water that meets international health and service standards.

Why RO Water Plants Are a Necessity in Hotels & Hospitals

a) Common Water Challenges

Water sourced from municipal supplies or borewells often contains high TDS (Total Dissolved Solids), microbial contamination, hardness, and chemical pollutants.

Without proper purification, this can result in:

- Foul taste and odor in drinking water

- Scaling in pipelines, appliances, and medical devices

- Health risks for patients, staff, or guests

- Reduced lifespan of sterilizers, boilers, and laundry equipment

b) How RO Solves These Problems

RO water plants use advanced membrane filtration to remove:

- Dissolved salts, heavy metals, and chlorine

- Bacteria, viruses, and organic impurities

- Hardness-causing minerals and unpleasant odors

Optional add-ons like UV/UF sterilization, TDS controllers, and pH correction units ensure water is not only pure — but also balanced, safe, and great-tasting.

How RO Water Plants Work (Overview)

- Pre-Filtration: Removes sand, dirt, and rust

- Carbon Filtration: Absorbs chlorine, pesticides, and organics

- RO Membrane: Filters out TDS, microbes, and chemicals

- UV/UF Disinfection: Kills remaining pathogens

- Mineral Rebalancing: Adds essential minerals & corrects pH

The result: Soft, sterile, and mineral-balanced water, suitable for every operational need in hotels and hospitals.

Combined Benefits for Hotels and Hospitals

Installing an RO water plant delivers multiple cross-functional benefits that apply to both sectors:

- Safe Drinking Water at All Points: RO ensures fresh, contaminant-free water for guest rooms, cafeterias, wards, and waiting areas.

- Enhanced Equipment Life: Prevents scale and corrosion in boilers, washing machines, sterilizers, dishwashers, and lab gear.

- Improved Hygiene and Health: Reduces infection risks and ensures compliance with standards like WHO, BIS, and NABH.

- Better Taste & Food Quality: Water used in kitchens leads to better-tasting food and beverages.

- Cost Savings Over Bottled Water: Reduces dependency on packaged water, saving significantly in the long term.

- Sustainable & Eco-Friendly: Reduces single-use plastic and supports environmental goals.

- Professional Brand Image: Demonstrates commitment to health, hygiene, and sustainability — key to reputation in both sectors.

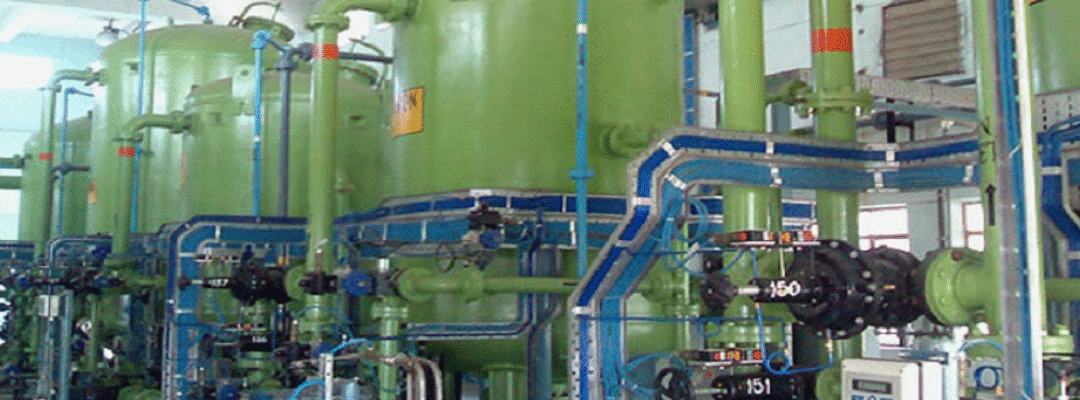

Features of a Commercial RO Plant

- High-capacity units (250–10,000+ LPH)

- Durable stainless steel or FRP body

- Auto-flushing membranes for longer life

- UV disinfection and smart TDS control

- Energy-efficient pumps with water recovery

- Manual, semi-automatic, or PLC-based automation

What to Consider Before Installation

Before choosing an RO system for your hotel or hospital, evaluate:

- Feedwater quality (TDS, hardness, microbial load)

- Daily water consumption across different departments

- Space and power availability

- Post-treatment needs (e.g., UV, mineral rebalancing)

- Support and service availability

- Compliance with local and healthcare water safety standards

Frequently Asked Questions (FAQs)

Q1. What RO plant capacity is ideal for hotels and hospitals?

Most setups require 250 to 10,000 LPH depending on size and daily consumption.

Q2. Is RO water safe for patients and medical use?

Yes. RO water meets BIS and WHO safety standards when systems are properly maintained.

Q3. Can hospitals and hotels eliminate bottled water?

Absolutely. A centralized RO system delivers fresh, safe water across the facility — reducing costs and plastic use.

Q4. How often should RO membranes be changed?

Typically every 2–3 years, with preventive maintenance every 3–6 months.

Q5. Are RO systems customizable?

Yes. They can be configured with UV, UF, pH adjustment, and mineral cartridges to meet specific usage requirements.

Recent Comments